Conveyor belts are a ubiquitous part of modern-day commercial methods. Silently running behind the curtain to transport substances and goods efficiently and reliably. While metal and rubber conveyor belts are typically recognized, fabric conveyor belts continue to be a hidden hero inside the global conveyance.

In this text, we will unravel the thread and explore the captivating international of cloth conveyor belts. Dropping light on their applications, blessings, and progressive answers provided by manufacturers.

The Fabric Conveyor Belt: An Unsung Hero

Fabric vs. Steel and Rubber: The Fundamental Difference

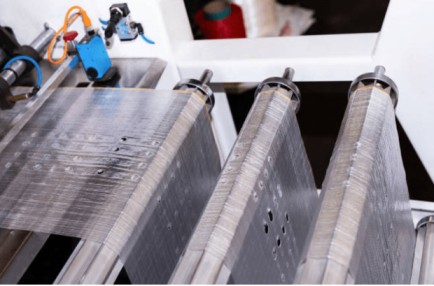

Fabric conveyor belts, as the name indicates, are made from more than one layer of cloth materials. These layers are commonly crafted from synthetic fabrics like polyester or nylon. They are decided on for their energy, flexibility, and durability.

The key distinction between cloth conveyor belts and their steel or rubber counterparts lies in the composition. While metal belts are fabricated from interlinked metallic portions and rubber belts consist of layers of rubber and reinforcement substances. Cloth belts are composed of layers of material fabric coated with rubber or different compounds.

Innovating Fabric Conveyor Belt Solutions

Innovating fabric conveyor belt solutions is pivotal in modern industry. With ever-evolving demands for increased efficiency, durability, and sustainability, fabric conveyor belts are undergoing a remarkable transformation.

Engineers and manufacturers are relentlessly exploring advanced materials and construction techniques, aimed at optimizing conveyor belt performance.

Through the utilization of state-of-the-art polymers and textiles to enhance wear resistance and reduce energy consumption. Along with innovative design features for smoother tracking and reduced maintenance. These breakthroughs are reshaping material handling s across diverse sectors.

This commitment to innovation not only streamlines logistics and production processes. But also fosters a more eco-friendly and cost-effective industrial landscape. For more information, visit Monster Belting to explore the latest advancements in fabric conveyor belt solutions and how they can benefit your specific industry needs.

Diverse Applications: Where Fabric Conveyor Belts Shine

Fabric conveyor belts find packages in a huge range of industries due to their versatility and reliability. Some of their commonplace packages include:

Agriculture: In agriculture, fabric conveyor belts are used for mild dealing with vegetation, consisting of grains, seeds, and results, lowering the threat of harm during transportation.

Mining: Fabric belts are applied in mining operations to move materials like coal, ore, and aggregates. Their flexibility and electricity cause them to be perfect for difficult, choppy terrain.

Food Processing: The food enterprise is based on cloth conveyor belts to move meal merchandise via diverse ranges of production, from washing and reducing to packaging.

Airport Baggage Handling: At airports, material conveyor belts are accountable for effectively transporting passengers’ luggage from test-in to the plane and vice versa.

Manufacturing: Fabric belts play a crucial position in manufacturing industries. Facilitating the movement of merchandise along assembly traces and among workstations.

Logistics and Distribution: In warehouses and distribution centers, cloth conveyor belts are crucial for the streamlined movement of programs and goods.

Advantages of Fabric Conveyor Belts

Fabric conveyor belts offer numerous advantages that make them a preferred desire in many industries:

Flexibility: Fabric belts are more flexible than metallic belts. They makes them appropriate for applications that require turning or navigating through tight areas.

Strength: These belts have excessive tensile power, allowing them to handle heavy masses without stretching or breaking.

Reduced Noise: Fabric belts function quietly, making them ideal for industries in which noise reduction is essential.

Cost-Efficiency: Fabric belts are frequently more powerful than steel belts, making them a cheap choice for many programs.

Easy Repairs: When damaged, fabric belts are commonly less difficult to restore than their steel counterparts, reducing downtime and renovation fees.

Lightweight: Fabric belts are lighter than steel belts, which can simplify setup and reduce the burden on conveyor structures.

The Future of Fabric Conveyor Belts: A Glimpse Ahead

As industries continue to adapt and adapt to converting needs and environmental issues. The destiny of fabric conveyor belts is ready to be even more promising.

Here’s a glimpse into what the future might also maintain for those unsung heroes of material coping with:

1. Enhanced Durability: With advancements in substances and manufacturing strategies, cloth conveyor belts are getting even more durable. They can be capable of withstanding harsh environments, abrasive materials, and extreme temperatures.

2. Sustainability Focus: In line with international sustainability efforts, fabric conveyor belts should be extra environmentally friendly. This will include using green materials and designs that limit energy consumption and reduce waste.

3. IoT Integration: The integration of the Internet of Things (IoT) generation will permit for actual-time monitoring and predictive maintenance of cloth conveyor belts. This will assist in lowering downtime and improving efficiency.

4. Automation and Robotics: As automation and robotics play a more good-sized function in diverse industries, cloth conveyor belts become an integral part of these s. They will facilitate the movement of substances through extraordinary automatic procedures.

5. Customization and Efficiency: Fabric conveyor belts will stay customized to match the particular needs of various industries and packages. Improved designs will focus on maximizing performance whilst minimizing power intake.

6. Smart Belts: Fabric conveyor belts may also emerge as “smart belts” prepared with sensors and data analysis competencies. These belts can be capable of coming across problems in actual time, consisting of put-on and tear, and cause upkeep signals earlier than a prime breakdown happens.

7. Advanced Materials: The use of advanced materials, consisting of carbon nanotubes and graphene. Will in addition enhance the power and sturdiness of fabric conveyor belts. These substances will provide awesome overall performance, even in the cruelest situations.

8. Increased Automation in Agriculture: In agriculture, cloth conveyor belts could be widely used for harvesting, sorting, and packaging. This accelerated automation will help enhance the efficiency of meal manufacturing.

Conclusion

Fabric conveyor belts, even though frequently overshadowed by their steel and rubber counterparts, are an essential element of many industries. Their flexibility, strength, and fee-effectiveness lead them to a reliable preference for applications ranging from agriculture to production. Monster Belting, with its dedication to quality, innovation, and sustainability, is leading the manner in imparting advanced material conveyor belt answers that meet the evolving needs of industries around the arena.