Surface Mount Technology (SMT) revolutionized the way electronic components are assembled onto printed circuit boards (PCBs). An SMT line, also known as an SMT assembly line, is a specialized production line designed for the efficient assembly of electronic components using SMT techniques. It comprises various equipment and machinery tailored for precise component placement on PCBs.

Let’s delve deeper into the key elements, functions, and construction of SMT line:

Improved Speed and Efficiency: Automation in SMT Lines

Making Advanced Technologies Easier: SMT lines help with.

- Miniaturization: SMT lines help create little gadgets by putting together tiny parts.

- Complex Systems Integration: SMT techniques easily add fancy technology, like tiny computers and sensors, into products.

- High-Speed Data Processing: SMT lines put together parts to make things work fast in phones, computers, and networks.

- IoT Connectivity: SMT lines make IoT devices by adding sensors, communication parts, and connection features.

- Wearable Electronics: SMT lines put pieces on bendy stuff to make wearables like smartwatches and fitness trackers.

- Automotive Electronics: SMT lines make parts for cars, like ADAS and infotainment systems.

- Aerospace and Defense Systems: SMT technology creates electronic parts for airplanes and defense equipment, such as avionics and communication systems.

- Energy Efficiency: SMT lines help make electronics that save energy. They do this by putting together circuits that manage power and sensors that work well.

Using SMT lines helps companies make new products with the latest technology to meet today’s electronic needs.

Key Elements of an SMT Line

- Stencil Printing Component: This part applies solder paste to the PCBs. It helps ensure that the pieces are in the right place when making things.

- Picking and Placing Machines: These machines use special lights to pick up and place electronic parts on the circuit boards. This ensures that the parts are in exactly the right place and facing the right way.

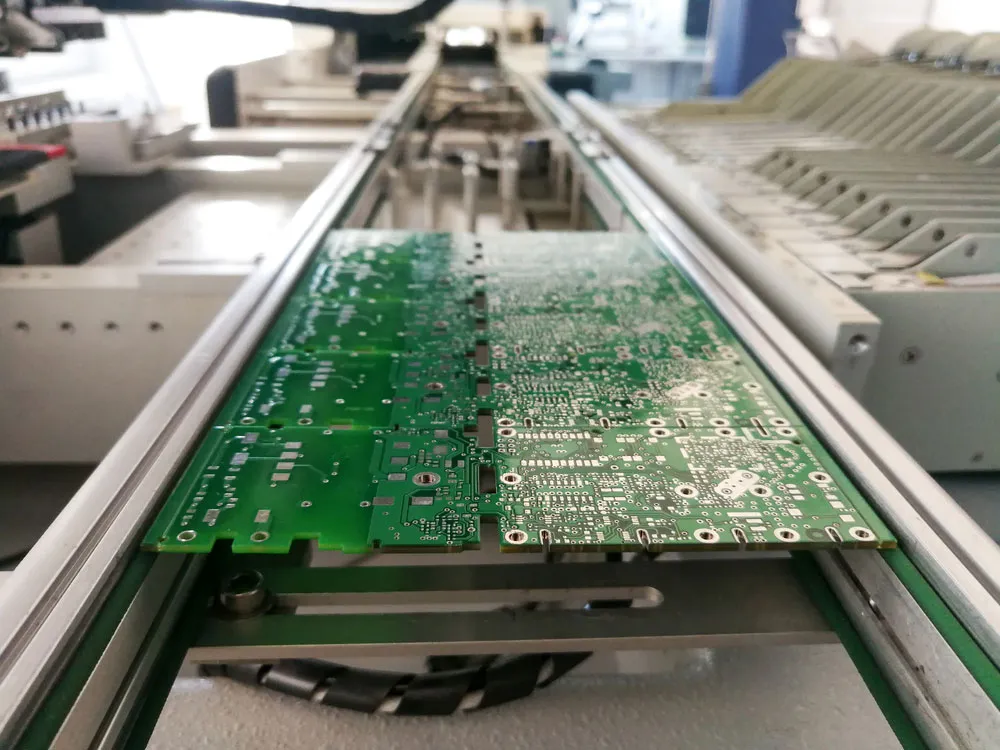

- Carrier Systems: Conveyor belts move circuit boards between assembly stations, making production run smoothly.

- Wave Soldering Equipment: This tool helps connect parts to circuit boards, working well with other assembly methods.

- Reflow-type Ovens: Warm up the solder paste until it melts, making sure the parts and circuit boards stick together well.

- Automated Optical Inspection (AOI) Systems: Scan and inspect assembled PCBs for defects, ensuring quality and reliability.

- Quality Monitoring and Assessment: We use different testing tools to check if assembled circuit boards work well and are dependable.

Role and Benefits of SMT Lines

Module Density and Reduction: SMT lines help connect small electronic parts, making it easier to create small and light gadgets.

Improved Speed and Efficiency: Using machines to build things faster helps make products quicker, meeting the need for speedier production and shorter waiting times.

Enhanced Reliability and Precision: SMT machines put parts in the right spots, making sure electronic systems work well and last long.

Quality Assurance: Automated inspection systems find problems quickly during assembly, ensuring the quality of the final products.

Facilitation of Advanced Technologies: SMT lines help put the latest technology into electronic stuff, pushing for new ideas and improvements in the business.

Cost Savings: Using resources better and making less waste saves money when making things.

Flexibility and Adaptability: SMT lines can handle different PCB setups and parts, so they work well for lots of electronic stuff and can change to fit what’s needed for making things.

Construction of SMT Lines

Design a good layout for the SMT production space. Make sure it helps work move smoothly and follows environmental rules.

Selection of Machinery: Pick the right SMT equipment for what you need to make, making sure it works well and is precise.

Configuration and Deployment: Install the chosen machines, such as computers, making sure they work with the software and are properly adjusted.

Workflow Optimization: Improve production, test it out, and improve the way things are done so we can do more in less time.

Personnel Hiring and Training: Teach and prepare people to run and care for SMT machines well, so our work keeps going smoothly with skilled workers.

Safety and Compliance: Follow the rules for safety and the law, make sure everyone has the right safety equipment, and do things in a way that keeps the environment safe.

Conclusion

SMT lines are really important in making electronics nowadays. They help put electronic parts onto PCBs quickly. Using fancy machines and automation, SMT lines make good products quickly and cheaply.

To make SMT lines work well, it’s important to plan, choose the right equipment, and properly train workers.