Ensuring the safety of electrical cabinets is essential to prevent accidents and keep things running smoothly. These cabinets hold circuit breakers, switches, and wires that power different systems. Safety means checking them often to find and fix problems like loose connections or damage.

Using safety gear like circuit breakers and surge protectors helps stop fires and equipment damage. Labels with clear instructions are important so people know how to use and fix things safely.

Training workers on safety rules and giving them gear to protect themselves makes things safer. When businesses prioritise safety for electrical cabinets, they can avoid problems, protect their staff, and keep working without interruptions.

Why is the safety of electrical cabinets important?

Safety of electrical cabinets safe is really important because they have parts like circuit breakers, switches, and wires that power things. Safety is vital to stop accidents, fires, and damage to equipment. Problems like loose connections, overheating, and broken insulation can cause short circuits and fires.

These dangers can hurt people and damage property around them. Also, making sure electrical cabinets are safe helps things run smoothly. If something goes wrong with the electrical system, it can stop work and cost a lot to fix.

Doing things like checking cabinets regularly and using safety devices like circuit breakers helps reduce risks. Training workers on safety and following safety rules make workplaces safer and prevent accidents. Taking care of electrical cabinets protects people and things, making work safer and more efficient.

What are some common hazards associated with electrical cabinets?

Safety of Electrical cabinets have some common dangers. Loose connections are risky because they can make things too hot and cause fires. Poor maintenance or overloading circuits can cause overheating, which is a significant problem.

If insulation is damaged, wires can be exposed, which might shock someone or cause a short circuit. If cabinets aren’t installed right or don’t have good grounding, there could be electrical faults and dangers. Not enough air flow in cabinets can make things even hotter, leading to failures.

Also, if cabinets aren’t labeled properly, it might be confusing during emergencies. So, to keep electrical cabinets safe, they need to be checked often, installed correctly, and follow safety rules.

How can we ensure the safety of electrical cabinets?

Making sure Safety of electrical cabinets is really important to stop accidents, fires, and damage to equipment. Firstly, check them regularly for any wear, damage, or loose parts. Fix any problems you find quickly. Also, it’s crucial to install safety devices like circuit breakers, fuses, surge protectors, and ground fault circuit interrupters (GFCIs) to prevent electrical problems.

Labeling cabinets with clear instructions helps people understand how to use them safely and spot dangers. Training workers on safety is also important. They need to know how to spot electrical hazards, use safety gear, and handle emergencies. By doing these things properly, businesses can keep electrical cabinets safe, protect their stuff, and keep working smoothly.

What safety devices should be installed in electrical cabinets?

To keep electrical cabinets safe and prevent accidents, it’s important to install different safety devices. Circuit breakers stop electricity if there’s too much or a short circuit, which could cause fires. Fuses break the circuit if there’s too much electricity, protecting the system.

Surge protectors shield equipment from sudden increases in power, like during lightning strikes. Ground fault circuit interrupters (GFCIs) stop power if there’s an imbalance in the current, especially in wet areas.

These devices help businesses reduce risks, keep people safe, and make sure electrical systems work well. Checking these devices regularly is important to make sure they’re still working properly and keeping things safe.

How often should electrical cabinets be inspected?

The frequency of checking safety of electrical cabinets depends on things like where they’re used, how often, and what rules there are. Usually, it’s good to check them every three to six months to make sure they’re safe and working right. But if they’re used a lot or in tough places, they might need checking more often, like every month or even every week. Some places have strict rules about how often you need to check them to follow the law.

When you check them, people who know what they’re doing should look really carefully for any problems. This means looking for things like loose parts, stuff getting too hot, or things that are broken. It’s important to make sure safety things like circuit breakers are working like they should.

If there’s anything wrong, it needs fixing fast to stop accidents. The main goal of checking often is to make sure everything is safe, protect people, and keep things working well.

Importance of electrical cabinets in industries

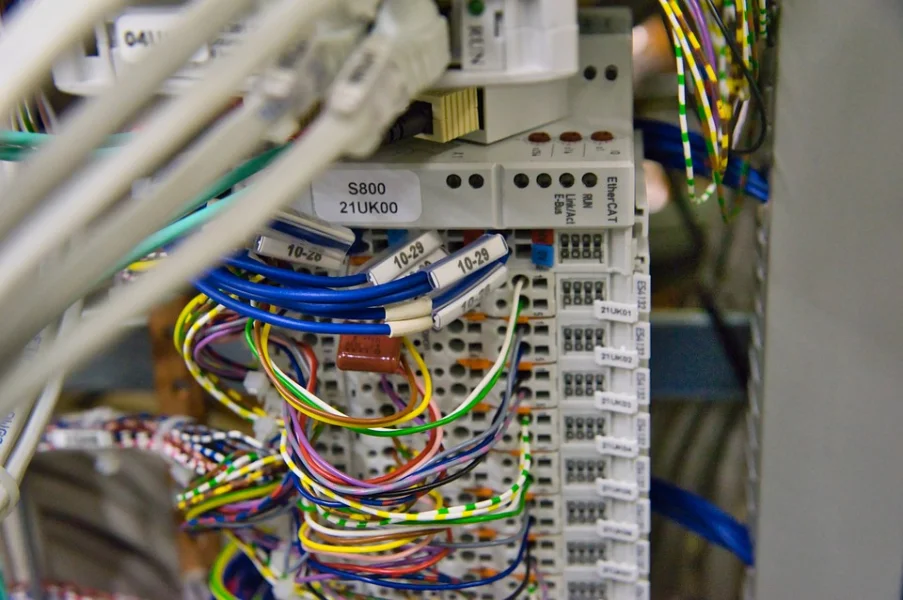

1. Equipment Protection: Electrical cabinets house sensitive and valuable electrical features. These include circuit breakers, switches and control panels. These components are essential to the process of machines and equipment. The cabinets protect them from environmental factors such as dust, humidity and physical damage, ensuring the uninterrupted operation of industrial processes.

2. Safety: Electrical cabinets contain potentially dangerous electrical connections and wires. They are designed to surround these items and stop accidental contact, reducing the risk of electric shock, fire and other accidents. Safety measures such as lock-out and tag-out procedures are often built into these cabinets to protect workers during maintenance and repair work.

3. Organization: Cabinets provide a centralized, organized location for electrical components and wiring. Proper cable management and labelling make it easier for maintenance personnel to troubleshoot problems, perform routine inspections, and complete repairs efficiently.

4. Security: Limited access to electrical cabinets prevents unauthorized personnel from tampering with electrical systems. This also increases security and reduces the risk of intentional or unintentional troubles to industrial processes.

5. Compliance: Several industries are subject to strict regulations and safety standards governing the installation and maintenance of electrical systems. Electrical cabinets are designed and installed by these regulations, which ensures compliance with legislation and reduces the risk of damages or operational shutdowns due to non-compliance.

6. Downtime Prevention: Properly maintained electrical cabinets reduce the likelihood of electrical failures and downtime. Regular inspections and maintenance of cabinet components help identify potential problems before they become costly failures.

7. Efficiency: Well-designed electrical cabinets optimize the layout of components, thereby reducing the length of electrical wires and cables. This helps minimize electrical losses, increase energy efficiency and improve the overall performance of industrial systems. You can visit plchmi.

Factors Influencing Safety of electrical cabinets

Many things affect how Safety of electrical cabinets are. First, where they are matters a lot. If they’re in places with bad weather or dangerous stuff, they can wear out faster and become unsafe.

How often and how much the cabinets are used is also important. Cabinets in busy areas or those that power really important stuff might wear out quicker and need checking more often to stay safe.

Rules about safety also matter. Different places have different rules about how electrical stuff should be kept safe. Following these rules keeps things from being dangerous.

Finally, how well the cabinets are installed and taken care of makes a big difference. If they’re put in right and checked regularly by people who know what they’re doing, problems can be fixed before they become dangerous.

All these things together decide how safe electrical cabinets are. By thinking about where they are, how much they’re used, following safety rules, and taking good care of them, we can make sure they stay safe and work well.

Signs of Electrical Cabinet Hazards

Spotting signs of danger in electrical cabinets is really important for keeping things safe. If you see wires that are loose or worn out, it’s a big warning sign. Loose wires can get too hot, spark, or even start fires, which is dangerous for people and equipment. Also, if you notice rust or corrosion on parts inside the cabinet, it could mean water is getting in, which can cause electrical problems.

Seeing burn marks or discoloration around parts is another sign of trouble. It means things might be getting too hot or not working like they should, which could lead to parts breaking or fires starting. Weird sounds like buzzing or crackling coming from the cabinet can also mean there’s a problem with the electrical stuff inside.

Lastly, if you smell something burning or overheating from the cabinet, you should act fast. Investigating and fixing the problem quickly can stop fires from happening. Checking the cabinet regularly for these signs helps keep everyone safe and makes sure things keep working well.

Addressing Issues Found in Inspections

When problems are found in electrical cabinets during checks, it’s really important to fix them quickly to keep things safe and avoid accidents. Fixing these issues means following a step-by-step plan to solve any problems and keep the cabinets working properly.

Depending on what’s wrong, fixes might include tightening loose parts, changing broken pieces, fixing wires, or making sure safety devices like circuit breakers are working right.

It’s super important to follow safety rules and instructions when fixing these issues to make sure everyone stays safe and follows the law. Trained workers should handle all the fixing jobs, using the right tools to do them safely and well. It’s also important to write down what issues were found and what was done to fix them for future reference.

By fixing problems quickly, businesses can stop accidents, protect equipment, and keep workplaces safe. Checking again later makes sure the fixes worked and everything’s still safe.

Overall Goal of Electrical Cabinet Safety Measures

The main goal of electrical cabinet safety is to keep people, equipment, and buildings safe from electrical dangers. Safety protocols are put in place to reduce the chances of accidents, injuries, fires, and damage to equipment. This includes things like checking cabinets often, installing safety devices correctly, and following rules and standards.

Training workers on safety helps too. When cabinets are safe, businesses avoid problems and don’t lose money from broken equipment or accidents. Also, when safety is a big deal at work, employees feel good and are more likely to spot and fix problems before they cause trouble.

The big aim is to make sure everyone can work safely and confidently. Regular checks, always trying to do better, and sticking to safety rules all help reach this goal and keep operations running smoothly for a long time.

Safety instructions for electrical cabinets

Proper cabinet design: Ensure cabinets are designed and built to industry standards, with sufficient space for components and good ventilation.

Ventilation: Maintain adequate ventilation to disperse heat generated by electrical elements to prevent overheating and fires.

Labelling: Label cabinets to identify circuits, voltage, and potential risks to facilitate quick identification in maintenance or emergencies.

Regular inspections: Perform routine checks to spot damaged cables, loose connections or overheating signs, and promptly address problems.

Maintenance Schedule: Establish a schedule to replace worn components and keep cabinets in optimal condition.

Lockout/Tagout Procedures: During maintenance, implement lockout/tagout procedures to prevent accidental energization and protect workers.

Employee Training: Provide employees with comprehensive electrical cabinet safety training, including hazard recognition and emergency measures.

Proper Grounding: Ensure cabinets are properly grounded to avoid electrical shock and minimize static electricity discharge.

Cable Management: Organize and secure cables to prevent tripping hazards and wire damage.

Emergency Response Plan: The company must develop an emergency response plan that includes shutdown procedures and contact information for rapid response during an electrical emergency.

Fire Suppression: Install fire suppression systems near cabinets to quickly extinguish fires in the event of an electrical malfunction.

Documentation: Maintain records of maintenance, inspections, and any modifications to electrical cabinets for reference and audit purposes.

Conclusion

In conclusion, making sure Safety of electrical cabinets is really important to keep everyone at work safe and avoid problems. Checking them regularly, fixing any issues, and using safety devices like labels and training workers are all crucial.

Following safety rules and doing things to prevent problems helps protect people, things, and the work we do. So, investing in safety for electrical cabinets doesn’t just make work safer but also helps things run smoothly and keeps us productive.

FAQs

The main goal is to create a safe working environment where personnel can operate confidently and efficiently without compromising safety.

Safety measures prevent downtime caused by accidents or equipment failures, ensuring uninterrupted operations.

Address the issue promptly by shutting off power and contacting a qualified electrician for repairs.

Yes, adherence to industry standards and regulations is crucial for safety compliance.

Yes, adherence to industry standards and regulations is crucial for safety compliance.