Polyethylene is the most common and widely used plastic in the world. Polyethylene has a simple molecular structure and a broad range of applications. It is ubiquitous, used in everything from children’s toys to food bags to bottles. The most common types are Low-Density Polyethylene LDPE vs HDPE High-Density Polyethylene.

This article, will delve into the differences between LDPE and HDPE, helping readers to understand better the advantages and disadvantages of these materials, as well as their applicability in various applications.

Overview of LDPE & HDPE

HDPE is a kind of hard plastic made by mixing ethylene molecules.

It’s made under low pressure with special chemicals called Ziegler-Natta catalysts, which is why it’s also called low-pressure plastic.

On the flip side, LDPE is made under high pressure using oxygen or special chemicals called organic peroxides. That’s why it’s also called high-pressure plastic.

Both LDPE and HDPE are types of polyethylene. Their different chemical structures and physical properties make them suitable for different uses.

LDPE vs HDPE: Properties

Low-density polyethylene is the lightest type of polyethylene. It looks like small, white, waxy beads. They don’t smell, taste, or harm you if you touch them.

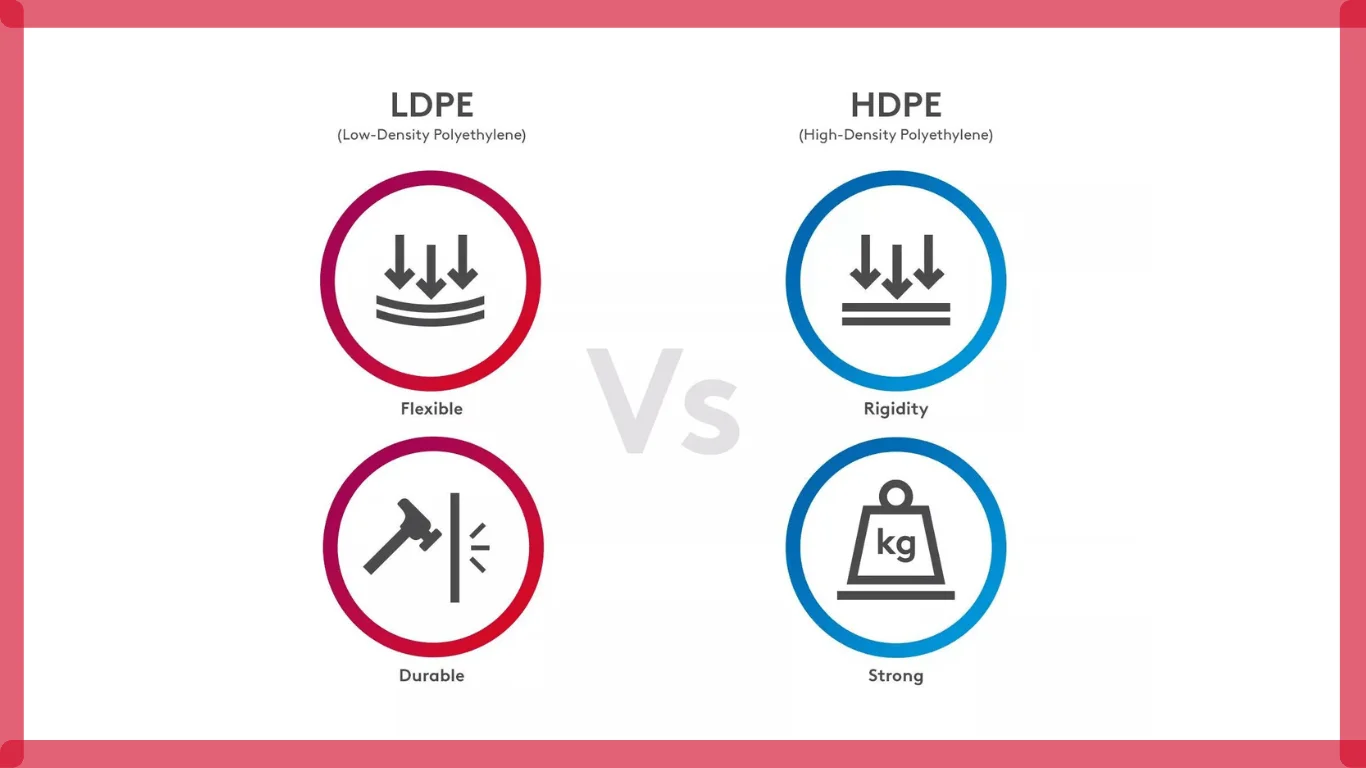

Low-density polyethylene is not very organized on a tiny level. It can bend a lot, stretch, stop electricity, let light through, and resist getting hit hard.

But it’s not strong and can’t handle heat well. It can also break easily when it’s under stress from the environment.

HDPE is safe to use because it doesn’t have any harmful chemicals, taste, or smell, and its density is between 0.940 and 0.976 grams per cubic centimetre.

When HDPE is natural, it looks like a milky white colour, and when it’s thin, you can somewhat see through it.

It’s really good at resisting many household and industrial chemicals, like strong cleaning products or acids. It can also handle stuff that can make things rust or break down, like concentrated nitric acid.

HDPE doesn’t soak up water, and it’s good at stopping water vapour, so it’s great for things that need to stay dry, like waterproof containers.

LDPE vs HDPE: Pros And Cons

Low-density polyethylene is liked because it can bend easily, making it great for squeeze bottles and bendy containers.

It’s see-through and clear, which helps a lot when packaging things that you need to see inside.

Low-density polyethylene can handle being hit without breaking in cold temperatures, so it stays strong in different environments. Also, it melts more easily, which saves energy when making things from it.

But it’s not as strong or stiff as high-density polyethylene, so it’s not as good for tough jobs.

Its lower heat resistance means it can’t be used in really hot places and it’s more likely to crack under stress, which makes it less useful in some situations.

HDPE is admired for being very strong and stiff, so it’s often used in tough jobs like making pipes and strong containers.

Because it can handle heat better, it’s good for hotter situations, and because it’s really resistant to chemicals, it’s perfect for storing chemicals at home or in factories.

HDPE is also easy to recycle, which is good for the environment, but it’s not as flexible as LDPE, which might limit its use in certain situations.

Because it melts at a higher temperature, it’s harder to work with HDPE, which might mean more energy or special machines are needed. And because it’s better quality, it might cost more than LDPE.

What are the advantages of using polyethylene?

Which Is Safer: LDPE or HDPE?

LDPE has a strong chemical structure that stays stable in normal situations, stopping harmful substances from getting out. It doesn’t have risky extras like phthalates.

But LDPE containers shouldn’t be used in hot places, like microwaves, because they might break down or let chemicals move around.

Therefore, when considering “Is LDPE safe” it is deemed safe for its intended uses within specific temperature limits.

HDPE is a strong and steady type of plastic. It isn’t easily damaged and doesn’t absorb much water, so it’s great for storing food.

The Food and Drug Administration thinks HDPE is safe for food. They even gave it a special symbol, “2,” to show it’s safe.

Also, HDPE can handle heat better than LDPE. This means it’s good for things that need to be in hot places.

So, regarding the question “Is HDPE safe?” the answer is a resounding yes.

Applications of LDPE And HDPE

Applications of LDPE

- Packaging: LDPE is widely used to make bendy packaging, such as plastic bags for shopping, bread and frozen food, and squeezed bottles. It’s chosen because it’s flexible and can resist moisture.

- Agricultural Films: Its ability to resist water and chemicals makes it good for plastic films used on farms to cover soil or greenhouses.

- Consumer Goods: LDPE is used in toys, squishy bottles, and food containers because it’s safe and flexible.

- Construction: LDPE is used in building things like water pipes and hoses because it doesn’t soak up water much and can bend easily.

- Medical Applications: Because it is safe and can resist chemicals, it’s good for making certain medical tools and supplies.

Applications of HDPE:

- Containers: HDPE is very strong and stiff, which makes it perfect for tough containers like milk jugs, detergent bottles, and large food storage tubs.

- Pipe Systems: HDPE is strong and doesn’t react much with chemicals. It’s used in pipes for water, gas, and sewers, and in fire sprinkler systems.

- Industrial Packaging: HDPE lasts a long time and can handle rubbing without damage, so it’s good for barrels, fuel tanks in cars and storage tanks.

- Consumer Goods: Because it’s safe and robust, HDPE makes toys, hard hats, and outdoor furniture.

- Geosynthetics: HDPE is used in geomembranes for landfill liners and as a barrier to contain or control fluids.

Summary

HDPE and LDPE are two kinds of plastic called polyethylene. HDPE is strong and stable because it has high density. It’s great for things that need to be tough and last a long time.

On the flip side, LDPE is known for being flexible, can handle low temperatures, and is easy to work with. It’s perfect for things that need to bend and seal well.

Deciding whether to use HDPE or LDPE depends on your needs. You have to consider what the material will do and how well each one will work for that job.

FAQ’s about LDPE (Low-Density Polyethylene) vs HDPE (High-Density Polyethylene):

Q1: What is the difference between LDPE and HDPE?

A1: LDPE and HDPE are both types of polyethylene, but they differ in their molecular structure and properties. LDPE has a lower density and is more flexible, while HDPE has a higher density and is stiffer.

Q2: What are the typical applications of LDPE and HDPE?

A2: LDPE is commonly used for packaging films, plastic bags, and squeezable bottles, while HDPE is often used for containers, pipes, and plastic lumber.

Q3: Which is more recyclable, LDPE or HDPE?

A3: LDPE and HDPE are recyclable, but HDPE is more commonly recycled due to its higher density and easier processability.

Q4: Which is more durable, LDPE or HDPE?

A4: HDPE is generally more durable and resistant to impact and environmental stress cracking than LDPE.

Q5: Are LDPE and HDPE safe for food contact?

A5: Yes, both LDPE and HDPE are approved for food contact applications and are considered safe for storing and packaging food.