Are you looking to unleash your creativity and bring your ideas to life? Look no further than an FDM printer! This incredible technology allows you to create anything from simple toys to complex mechanical parts. But where do you start if you’re new to 3D printing?

In this blog post, we’ll provide tips for beginners on how to get started with an FDM printer and share some printing tips and tricks along the way.

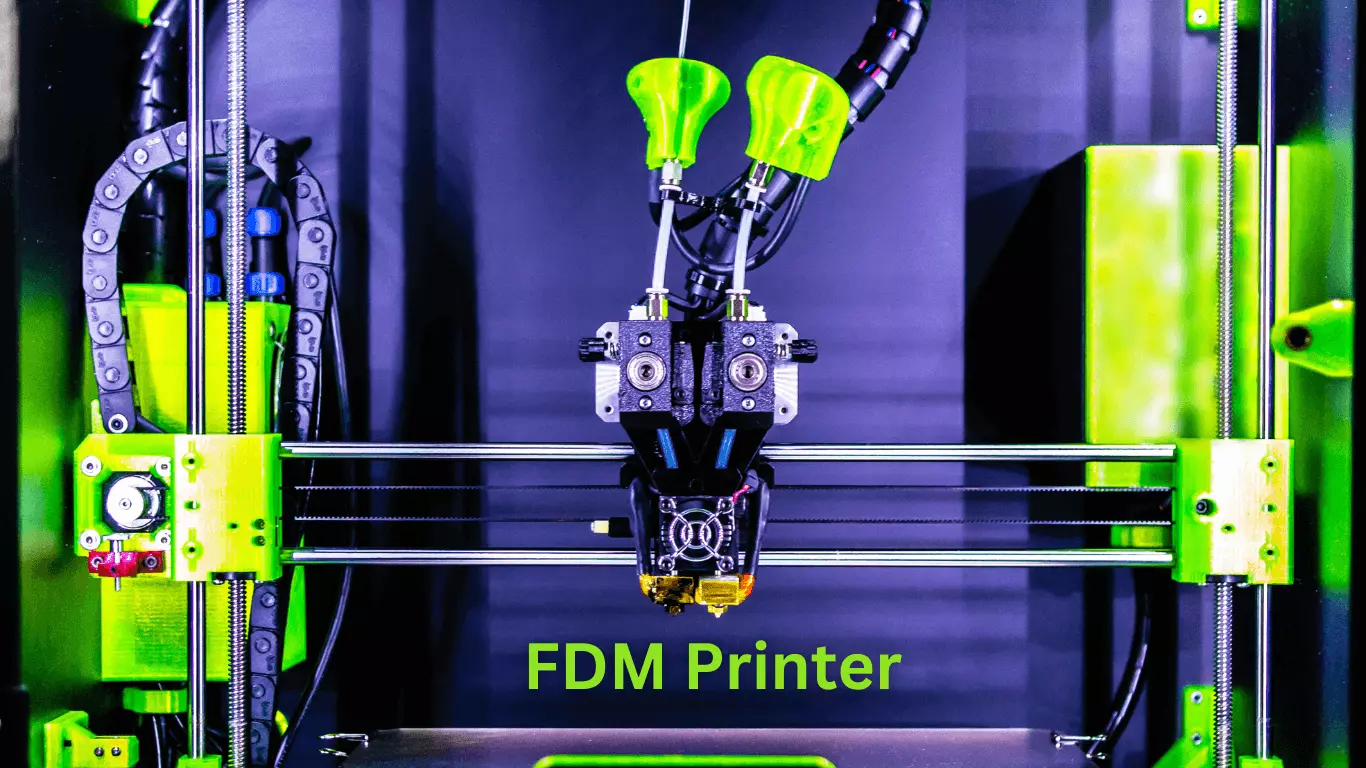

What is an FDM printer?

An FDM (Fused Deposition Modeling) printer is a type of 3D printer. That works by melting a filament of thermoplastic material and extruding it layer by layer to create a three-dimensional object. It’s widely used for rapid prototyping, manufacturing, and DIY projects.

How does an FDM printer work?

An FDM (Fused Deposition Modeling) printer works by melting a filament of thermoplastic material. Extruding it through a nozzle onto a build platform.

Here’s a simplified breakdown of how it operates:

- Filament Feeding: The printer feeds a spool of solid thermoplastic filament (like PLA or ABS) into a heated extrusion nozzle.

- Melting and Extrusion: The filament is heated to its melting point inside the nozzle. Once melted, it’s pushed through the nozzle’s tiny opening in a controlled manner.

- Layer-by-Layer Deposition: The nozzle moves horizontally and vertically according to instructions from a digital file (usually a CAD model sliced into layers). It deposits the melted filament onto the build platform in thin layers.

- Cooling and Solidification: As each layer is deposited, it quickly cools and solidifies. This process repeats, layer upon layer, gradually building up the object from the bottom to the top.

- Building Support Structures: For complex shapes or overhanging parts of the object. The printer may deposit temporary support structures made of the same or a different material.

- Completion: Once the printing is finished, the object is left to cool on the build platform. Depending on the complexity and size, prints can take from minutes to hours or even days.

An FDM printer transforms a digital design into a physical object by melting and depositing plastic layer by layer. Making it a versatile tool for prototyping, manufacturing, and DIY projects.

How do I ensure successful prints with my FDM printer?

Ensuring successful prints with your FDM printer involves several key steps that are crucial for achieving high-quality results:

- Calibrate Print Settings: Adjust settings such as layer height and infill density. Print speed according to the complexity and detail required for your print. Experimentation may be necessary to find the optimal settings for different projects.

- Level the Build Plate: Properly leveling the build plate ensures that the first layer adheres well to the print surface. Use a piece of paper or a feeler gauge to adjust the distance between the nozzle and build plate at various points until it’s uniformly leveled.

- Use Quality Filament: Choose high-quality filament that is appropriate for your project. Filaments like PLA are popular for beginners due to their ease of use and minimal warping. While materials like ABS may require a heated print bed to prevent warping.

- Ensure Adhesion: Use build plate adhesives like glue sticks or hairspray to help the first layer adhere securely to the bed. This prevents warping or lifting during printing, especially for larger or more complex prints.

- Monitor the Print Job: Stay near the printer during the initial printing layers to catch any issues early. This allows you to adjust settings or intervene if necessary. Minimizing the risk of print failures.

- Post-Processing: After the print is complete, remove it from the build plate using a scraper or spatula. Clean up any support structures or rough edges as needed, depending on the complexity of your design.

By following these steps, you can significantly increase the likelihood of successful prints with your FDM printer. Each print may require adjustments based on specific requirements.

So, don’t hesitate to fine-tune settings and techniques to achieve the best results.

Tips for Getting Started with an FDM Printer

Getting started with an FDM printer can seem intimidating. But don’t worry – it’s not as complicated as it may seem. Here are some tips to help you get started.

Make sure you choose the proper print settings. This means selecting your project’s correct layer height, infill density, and speed. Each stage affects the quality of your print. So, take your time to experiment and find what works best for you.

Consider using a build plate adhesive such as hairspray or glue stick. Ensure your prints stick firmly to the build surface without warping or shifting during printing. It’s also important to level your build plate before every print job.

When choosing filaments for your projects, remember that different materials have different properties, such as strength and flexibility. PLA is a popular choice for beginners due to its ease of use and affordability.

Before hitting “print”, always double-check the slicing software-generated code file. It will be sent from slicer software into 3D printer firmware. This ensures successful printing operation without any errors or problems.

Never leave your 3D printer unattended when in operation since there is always a risk of fire hazards if safety precautions aren’t taken seriously.

Printing Tips and Tricks

Printing with an FDM printer can be daunting, especially if you’re new to the process. However, you can unleash your creativity and achieve stunning results with the right tips and tricks.

One crucial tip for successful 3D printing is bed leveling. The printer’s build plate must be balanced correctly to ensure the printed objects adhere well and have a smooth surface finish. You can use a piece of paper or a feeler gauge to check each point on the bed to get it level.

What is the LONGER Laser B1 30W?

The LONGER Laser B1 30W is a high-precision laser-cutting machine with exceptional accuracy and speed. It utilizes advanced technology to produce intricate cuts on various materials, including wood, acrylic, paper, and leather.

One of the standout features of the LONGER Laser B1 30W is its powerful 33-watt laser source. This state-of-the-art source lets the machine cut through thicker materials easily and precisely.

Some ideas for using a 20W Laser Engraver in your work

Customized Gifts

A personalized gift shows how much thought and effort you put into a present. With a 20W Laser Engraver, you can create custom designs on wine glasses, phone cases, jewelry boxes, or cutting boards.

Home Decor

Upgrade your home decor with customized pieces such as engraved wooden signs, wall art or coasters. Use materials like wood, leather or acrylic to add texture and dimension to your designs.

Conclusion

An FDM printer is a valuable tool for unleashing your creativity and bringing your ideas to life. With these tips and tricks, beginners can use their FDM printers confidently. Knowing they know to troubleshoot any issues.