Laser cutting is a precise method used in many industries. It’s important to know its benefits. Laser cutting is accurate, works with many materials, is fast, and creates little waste, changing how things are made.

It’s better than old methods like plasma and water jet cutting because it’s more precise and works with more materials. It’s used in cars, planes, electronics, jewellery, and more, making production better.

It’s also used in medicine, signs, buildings, and art, making manufacturing better for the future.

The Advantages of Laser Cutting Services

1. Precision

The strong laser beam cuts very precisely, making tiny cuts accurately. This helps make complicated designs easily, so laser cutting is great for things that need to be very accurate.

2. Versatility

Laser cutting can cut many different materials like metal, plastic, wood, leather, and fabric. It can cut thin or thick materials.

Because of this, laser cutting in many industries like aerospace, cars, electronics, signs, and jewellery.

With laser-cutting machines, you can make detailed designs and shapes. This helps personalize things when making them.

Laser-cutting machines cut things fast, which saves time compared to the old ways. This speed is really helpful in big factories where getting things done quickly matters a lot. Laser cutting helps businesses finish jobs fast, which helps them stay ahead in the market.

4. Minimal Material Waste

Laser cutting saves materials by cutting them efficiently. It’s better than old methods like sawing or drilling because it makes smaller cuts, wasting less material.

Also, laser cutting is very precise, so parts can be put close together to use up more material and make less waste.

This helps businesses save money on materials and helps the environment by making less trash. In total, laser cutting helps companies work better and make more money while being good for the environment.

The two cutting methods most comparable to laser cutting are plasma cutting and water jet cutting. The advantages laser cutting enjoys as compared to the two above-mentioned cutting methods include:

Plasma Cutting

Laser cutting is better than plasma cutting because it has these benefits:

- Precision: Laser cutting is more precise than plasma cutting. Plasma cutting can be okay for precision, especially with thicker materials, but it usually makes wider cuts and isn’t as accurate as laser cutting.

- Versatility: Laser cutting is better than plasma cutting because it can cut more things, like plastic, wood, and fabric, not just metal. Plasma cutting is good for metal, especially thick metal.

- Material Waste: Laser cutting doesn’t waste much material because it cuts really thin lines and is super accurate. Plasma cutting, on the other hand, usually cuts wider lines and wastes more material, especially with thinner stuff.

Waterjet Cutting:

In the case of water jet cutting, laser cutting is more advantageous because of the following factors.

- Speed: Laser cutting is faster than waterjet cutting, especially with thin stuff. The laser beam cuts fast, great for making lots of things quickly. Waterjet cutting uses pressurized water with tiny abrasive bits, which can be slower.

- Precision: Laser cutting is usually more precise than waterjet cutting, especially for detailed designs and small parts. The laser beam can make very accurate cuts with little heat damage. Waterjet cutting can also be precise, but it might not be as accurate as laser cutting for some jobs.

- Suitability for Different Materials: Laser cutting can very accurately cut lots of different materials, like metal, plastic, and wood. It’s great for thin to medium-thick materials. Waterjet cutting is also good at cutting different things and works well for stuff that can get messed up by heat, like some metals and stones.

Laser cutting is better because it’s really precise, can do lots of different things, is fast, and doesn’t waste much material. Plasma and waterjet cutting are good too, but laser cutting is the top choice for a lot of industries.

Industry Applications of Laser Cutting Services

Laser cutting is very important in lots of industries. It helps make things very accurately and quickly. It’s used for making car parts, lightweight aeroplane pieces, and even designing jewellery.

Understanding how laser cutting is used in different industries is really important for making things better, faster, and exactly how people want them.

Manufacturing

Laser cutting is used in many industries to make different things. In electronics, it makes small parts for devices like circuit boards. Cars are made with precise parts cut by lasers for their frames, insides, and special parts like where airbags go.

Aeroplanes also use laser cutting to make light parts that help the plane use less fuel and carry more stuff. People who make jewellery use lasers to make pretty designs and cut gemstones just right.

Laser cutting is great because it’s very accurate, making parts exactly how they need to be. It’s fast, too, helping companies make things quickly while still being precise.

Laser cutting can cut all sorts of materials, from thin metal to thick plastic, making it really useful for making things today.

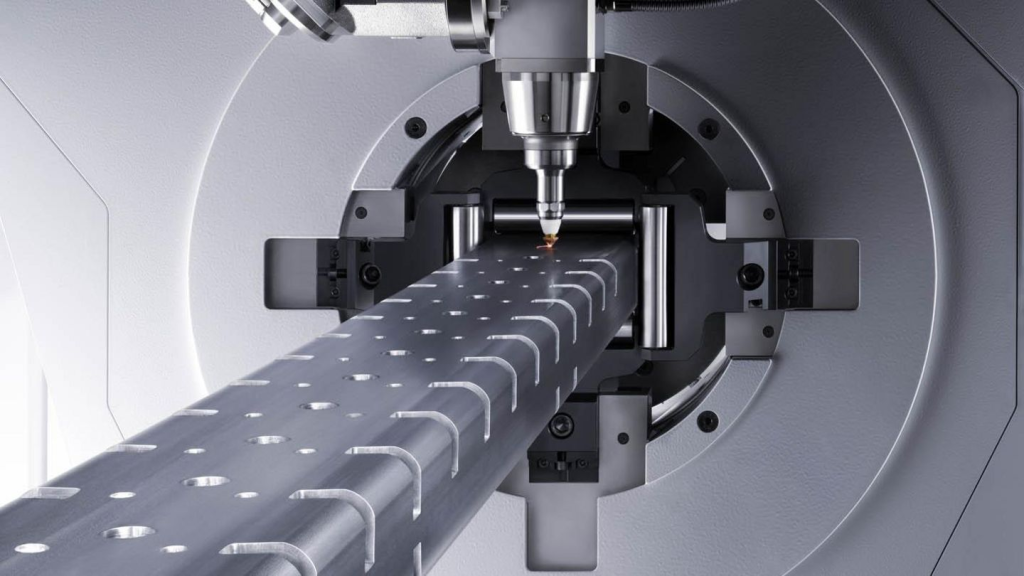

Laser cutting technology

Automotive

Laser cutting is like a superhero tool for making cars. It helps a lot in making different parts of cars, like the frames and inside pieces, making sure everything is just right.

Manufacturing Automotive Frames

Laser-cutting machines use computer models to guide them. They shoot a beam of light to cut metal pieces very accurately and fast.

This makes parts like beams and pillars for cars. After cutting, the parts are put together using welding or bolts to make the car’s frame.

Specialized Holes for Airbags

Engineers plan the airbag system, deciding where to put holes and how big they should be for the best results.

They get the material ready, usually a fabric or plastic cover, to be cut by lasers. Laser machines are given instructions about the hole design.

Then, the laser cuts the material very precisely to make the small holes needed for the airbag to work.

Aerospace

Laser cutting is super important in making parts for planes. It helps make lightweight parts very precise. Keeping the weight down is really important in making planes because that affects how much fuel they use and how much stuff they can carry.

Adaptable for a Variety of Materials

Laser cutting is great because it can make detailed parts from many light materials, such as aluminium, titanium, and composites. This works well for the aerospace industry, which needs strong, precise parts to keep planes safe and working well.

Electronics

In making electronics, laser cutting is really important. It helps with lots of different jobs, like making circuit boards, cutting parts, and putting together complicated electronic stuff.

Ultra Modern PCBs

Laser cutting is very important for making printed circuit boards (PCBs). It involves these steps:

- Design: We use special computer programs to make PCB designs. These designs show where to put the parts, wires, and copper on the board.

- Substrate Preparation: Making a printed circuit board (PCB) starts with preparing a special material. This material, usually fibreglass and epoxy, is like the foundation for building the circuit.

- Copper Cladding: Copper foil gets stuck onto the material underneath, covering both sides. This copper foil helps electricity flow in the circuit lines.

- Imaging: A layer of photosensitive material, called resist, is applied to the surface of the copper-clad substrate. The PCB design is then transferred onto this resist layer using a photographic process, creating a pattern that corresponds to the desired circuit layout.

- Laser Exposure: Laser cutting technology helps take off a covering called resist material from a copper-covered base. It shows the copper below in the shape of the circuit. This method is super exact, making it possible to create detailed circuit designs with exact sizes.

- Etching: The copper that’s not needed gets removed with chemicals, leaving the circuit on the board. A special material called resist keeps the copper we want safe, so only the extra copper goes away when we etch.

- Drilling: Laser or mechanical drilling creates holes in the PCB. These holes are called vias. They’re used to mount components on the board and connect electricity between its different layers.

- Component Mounting: Special parts like resistors, capacitors, tiny circuits, and connectors get put onto the PCB using machines.

- Soldering: The components are soldered onto the PCB to establish electrical connections between them and the circuit traces.

- Testing: The finished PCB undergoes testing to ensure that all components function properly and that the circuitry is free of defects.

Jewellery:

Once the design is decided, special machines called laser cutters are used to cut the jewellery parts from the chosen material.

The laser beam follows a computer design and cuts through the material very accurately and quickly. This helps to make detailed shapes and designs that would be hard to do by hand.

Laser cutting can also carve words, patterns, or designs into the jewellery. It can even include personal messages, detailed patterns, or pictures.

Laser cutting is also used to work on gemstones very carefully. This involves cutting, shaping, and carving gemstones to make special designs and settings for jewellery.

First, the parts are cut and marked. Then, they are put together to make jewellery. This might involve using heat or other methods to connect the parts.

After that, they make the jewellery look nice and strong by polishing, adding a thin layer of metal, or putting in stones.

Other Industries:

Laser cutting is used in many different industries, not just cars, planes, and electronics. It’s also used in medical equipment, signs, buildings, and art.

Surgical Instruments for the Medical Sector

In medicine, laser cutting helps make surgical tools, implants, and parts for medical devices very accurately and safely.

Signage and Architecture

Laser cutting is used to create fancy designs, letters, and decorations for signs and buildings. It can be used indoors or outdoors.

Arts and Crafts

Artists and craftsmen use laser cutting to make detailed artwork. Laser cutting is also used in many industries to make things better and faster.

Conclusion

Laser cutting is really accurate and can be used in lots of different industries. It’s great for making things like cars, planes, electronics, and jewellery.

Laser cutting speeds up production and creates detailed designs well. It can also cut different materials precisely, helping companies stay competitive.

Industries are using laser cutting more and more. This helps them make things with more accuracy, make them special, and be better for the environment. This is changing how things are made and designed in the future.